Laser Hybrid Welding

- Home

- Industrial Automation Capabilities

- Robotic Welding

- Laser Hybrid Welding

What is Laser Hybrid Welding

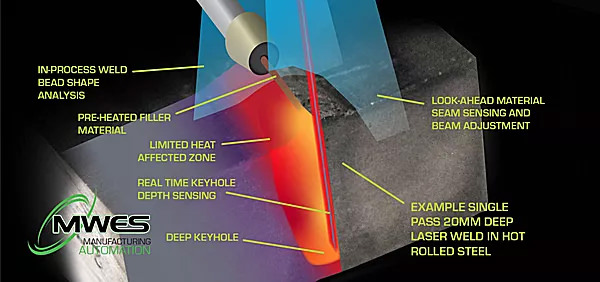

Laser hybrid welding is a process that uses a combination of laser and wire arc welding systems. Combined, these processes build on each’s strengths while reducing their weaknesses. More specifically, the system uses a laser to produce the weld keyhole while using a heated welding wire to fill the weld, much like wire arc welding. The process is ideal for heavy-duty welding applications found in shipbuilding, pressure vessels, armor plating and other areas where the thick metal plate is used.

The benefits of the system are recognized in the laser’s ability to produce a much deeper weld than with wire welding alone. This allows for effective single pass welding in materials that would usually take several passes with conventional wire arc welding alone. With laser hybrid welding, keyhole depths of 25mm in a single pass can be produced. Adding the ability to weld on both sides effectively doubles that depth for even thicker applications.

Hybrid laser welding’s high concentration of power has the added benefit of minimizing the heat absorption in the materials being welded as the system’s primary laser heat source results in a highly localized heat area. The much smaller heat-affected zone from the laser reduces material deformation away from the weld area. This reduces the need for post-weld heat-treating to correct bending or warping that develops using wire arc welding or other processes.

To ensure automated heavy plate welding success, MWES has developed a proprietary closed-loop feedback system that oversees the entire laser wire welding process. From recording the keyhole depth to assessing the finished weld dimensions, the feedback system monitors a number of parameters of the welding process in real-time and makes adjustments to the system as needed to guarantee the highest quality welds.

Combining the hybrid laser wire welding process with MWES’ robotic automation system’s capability allows for this process to be executed on a massive scale. Systems can be built that would allow heavy plate welding of parts up to 40 meters long. Robotic integration of the process also helps ensure a high degree of weld repeatability – which is already exceptional due to the fine-grain control laser heating inherently provides.

ADDere Additive Manufacturing

ADDere is designed to manufacture large-scale industrial parts in some of the most challenging metal-based materials. With our internally developed control systems, the ADDere laser-wire systems are capable of 3D printing high-quality, near net shaped metal deposition with post-processing taken into consideration.

Building the future of manufacturing, together

World-class Automation