Automated Knurling Machine

- Home

- Recent Projects

- Automated Knurling Machine

Project summary

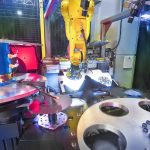

MWES integrated a turn-key fully robotic automation machine that performs a knurling process on automotive valve plates.

The Challenge

This firm sought out MWES to robotically automate a valve plate knurling manufacturing process for a high-volume automotive industry application. The robotic system had to be able to operate within the high pressure and high forces exerted by the knurling process. As well as perform all the operations with speed and quality assurance in mind. The automated production system had to be able to autonomously log part failure information to an operator interface.

The Solution

The automation solution MWES provided our customer with a compact robot cell that tends a pair of TOX 30-ton presses that are capable of handling four different part types. The robot is equipped with a magnetic gripper and 2D vision camera end-of-arm tool (EOAT). The system is equipped with a four-camera PPT vision system to detect the radial orientation of a part on the infeed conveyor to ensure correct orientation in the twelve-position dial table nest and flip any parts that are loaded upside-down.

Lastly, the system has built-in quality assurance throughout the knurling and handling process and the automation system can detect a wide variety of defects on the top and bottom surfaces of the part. The entire robot cell follows the safety guidelines of ISO 13849-1:2006 Category 3 and ANSI/RIA R15.06-1999 specifications.

Impact to the Customer

With the successful integration of the automated knurling machine MWES provided, our customer achieved increased productivity of 1800 parts per hour (one part every 2 seconds) all the while requiring 20% less floor space. Additionally, multiple sensors afforded them improved quality by detecting failures and immediately notifying the operator when issues arose and the system would automatically log and track the failures. Lastly, the robotic system utilizes fewer moving parts than the previous machine and less tooling to maintain, which in turn, increases the reliability and up-time of the process.

Midwest Engineered Systems has a wide range of experience in building custom robotically automated machines. If you’re looking to improve your manufacturing throughput, we have the knowledge and experience to make the project a success.

Contact us to learn how Midwest Engineered Systems can automate even your most complex and challenging operations today!

Innovation Through Automation

Client Details

A metal fine blanking company based in Wisconsin.