GMAW & GTAW Robotic Welding

- Home

- Industrial Automation Capabilities

- Robotic Welding

- GMAW & GTAW Robotic Welding

the Difference between GMAW & GTAW Arc Welding

The two most common types of gas arc welding are Gas Metal Arc Welding (GMAW), or Metal Inert Gas (MIG), and Gas Tungsten Arc Welding (GTAW), or Tungsten Inert Gas Welding (TIG). MIG welding uses a process where a continuous consumable wire electrode is heated and fed into the weld pool. As with TIG welding, an inert gas, such as argon, is also used as a shielding gas to protect the weld pool from any airborne contamination. MIG welding is widely used in most industry sectors. TIG welding uses a non-consumable tungsten electrode to create the arc with an inert shielding gas, such as argon or helium, to protect the weld pool from any airborne contamination. TIG welding is ideal for high-precision welding and welding with sheet metal.

What is MIG (GMAW) Welding?

The Gas Metal Arc Welding (or more commonly called ‘MIG’) process is straightforward and fast. It uses a continuous feed of a consumable wire electrode that is fed directly into the weld pool to form the weld bead. MIG welding provides fast production of high-quality welds with little to no slag being trapped in the weld pool. MIG welding uses a shielding gas made of an inert atmosphere of argon or helium to provide a clean weld pool and minimal weld splatter. It is also versatile enough that it can be operated semi and fully automatically when joining a variety of metals.

Automated GMAW welding systems can work with aluminum, stainless steel, regular steel and many non-ferrous materials, in thicknesses of 26-gauge, up to and including, large heavy-duty structural components. The simplicity and adaptability of the process make MIG welding a good choice for large, automated industrial operations that require high production rates. Since MIG uses a filler material, it can be used to weld two different materials together, whereas TIG simply fuses the two workpieces, thus requiring the two pieces to be of the same material.

A production line that utilizes a Gas Metal Arc Welding system tends to operate faster than one using TIG welding, while still creating high-quality welds. Also, parts for MIG welding systems are more readily available and far less expensive than their TIG counterparts. MIG welding requires less specialized training and experience to operate.

What is TIG (GTAW) Welding?

At the process’ core, TIG welding creates a small intense arc between a non-consumable tungsten electrode and the work surface. With its small intense arc, TIG is the most ideal welding process for high-quality and high-precision operations. The welding process utilizes a shielding gas that is made of an inert atmosphere of argon or helium. The purpose of the shielding gas is to protect the weld pool from any airborne contamination to create the purest weld. All of these operations have to be properly managed by a successful robotic system.

This type of welding can be performed vertically or in an overhead position and requires less complex equipment to operate, whereas TIG welding doesn’t require a spool to feed in. Also, TIG welding can be operated without filler metal in certain applications and can work in a larger range of different metals than MIG welding.

TIG welding tends to be a slower process that is primarily focused on fine detail and quality over speed. This aspect makes it highly compatible with robotic welding systems. Well-programmed automation can keep much more precise and repeatable operations than a human operator, especially at lower speeds.

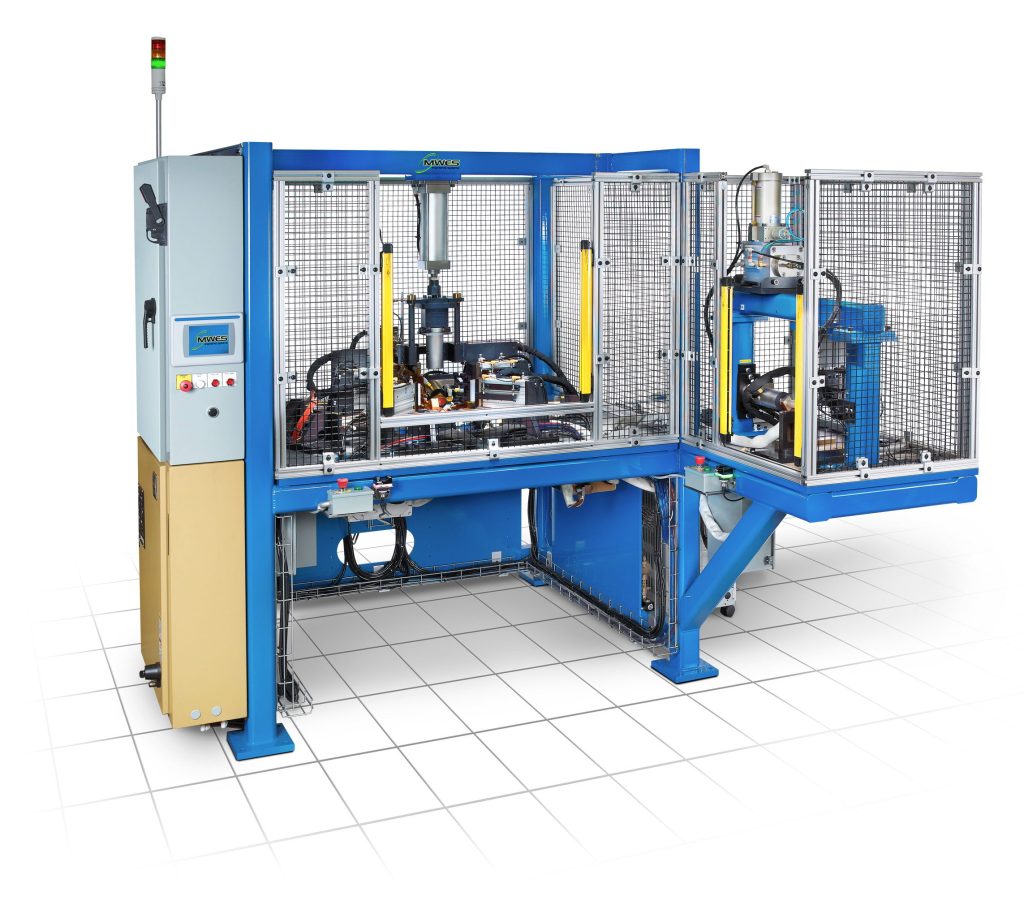

All of this put together indicates TIG welding to be a high-precision operation that requires deep knowledge and experience to automate properly. Midwest Engineered Systems has been designing, building and installing custom robotic TIG welding systems for many years. We have designed automated welding systems to handle a wide range of capabilities and weld procedures. To ensure the highest quality results, MWES employs Certified Robotic Arc Welding Technicians from a project’s onset to develop and guarantee the highest production performance of every system.

Building the future of manufacturing, together

World-class Automation